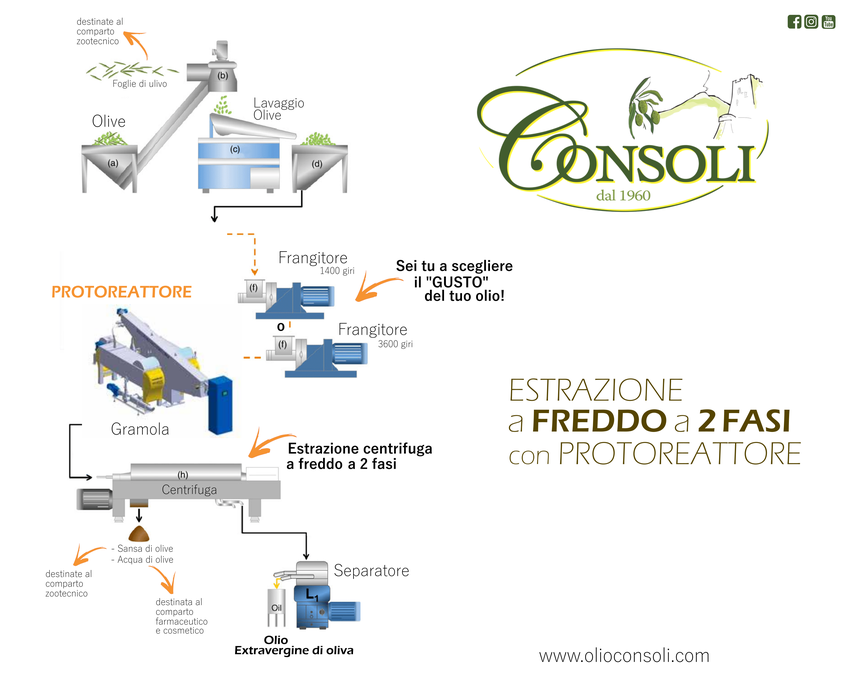

The olives for oil, after harvesting by hand or with the help of pneumatic harvesters, are transported to the oil mill and processed within 6 hours, so as to prevent the activation of maceration and oxidation phenomena that would ruin the quality of the extra virgin oil produced.

The Two-Stage Decanter

The olive paste after gramolation is pumped steadily toward a centrifugal separator with a horizontal axis called the Decanter. This makes it possible to separate from each other the two components present in the olive paste all with different specific gravity and consequently separable by centrifugal force:

- Oil

- Olive residues

The machine consists of a cylinder (called a drum) with a truncated end that rotates at about 3600 rpm and an internal auger, a continuous worm screw propeller to drain the pomace to the outlet, which rotates in the opposite direction to the drum at a speed of about 10-15 rpm.

The conical part of the drum and the respective part of the inner auger, refines the separation of solid from liquid, while the cylindrical part allows the separation of olive oil by a labyrinth and siphon system at the other end.

At one end of the machine is the electric motor drive that allows the drum to rotate. At the opposite end is normally placed an electric braking motor that regulates the revolutions of the internal auger that would otherwise be dragged by the drum full of olive paste.

The number of revolutions of the internal auger is variable and allows the machine's flow rate in quintals/hour to be adjusted. For the two-stage decanter, no water is added inside the decanter itself, but a small amount is added at the end of gramation to improve the viscosity of the olive paste.

With this technology, one has to be quite careful in calibrating the flow rate of the machine according to the differential speeds of the internal auger because if one is not precise, one runs the risk of not being able to remove all the oil from the pomace, resulting in yield problems.

Since from this type of decanter the olive oil comes out mixed with little water, you have to send the mixture to a single vertical centrifuge that will remove the little water from the oil. So great savings are achieved by using only one vertical centrifugal separator. The oil obtained will be quite bitter and very rich in polyphenols, precisely because of a reduced production of vegetation water whose disposal is a heavy cost.

Two phases or three phases? What changes for olive oil over time?

Cra Nut research analyzed the effects of two-phase and three-phase centrifugation systems on the organoleptic properties and chemical composition of unfiltered monovarietal oil evaluated at 1, 4, 7, 10 and 13 months after bottling. Statistical analysis was used to understand how technological variables affected sensory properties. Specifically, through Pls regression analysis, each sensory attribute perceived by the panel and, as independent variables, volatile compounds and polyphenols were assumed as dependent variables. All this was done to identify the molecules that contributed most to the comparative sensory differences.

The results showed, like other research previously, that the extraction system has a fundamental effect on sensory characteristics. Storage time also had a significant influence and affected sensory characteristics.

A significant change on the organoleptic profile was recorded at four months after bottling. After this period, there was effective stability of the oil until the end of the trial.

The 2-stage decanter was created to overcome the drawbacks of the 3-stage system. Basically, differing in the lower use of water by producing only two fractions (oil and wet pomace), this type of centrifugal extractor eliminates the problem of producing large amounts of vegetation water that is released directly into the pomace.

OUR PLANT

- Two-stage cold extraction

- protoreactor

The Protoreactor is a revolutionary machine for olive paste gramoling that can optimize time, reduce costs, but most importantly improve the quality of the final product. The new era of gramolatura begins with Pieralisi's Protoreactor. A unique system in the olive oil market with which the Pieralisi Group wins another first in the world of olive oil extraction.

The advantages of our Protoreactor

- Drastic reduction of gramoling time

- Improved oil quality with better organoleptic qualities (more polyphenols), and dramatic reduction of oxidation.

- 30% increase in polyphenols,

- number of peroxides reduced by 10%.

- increased oil shelf life

- increased sensation of spiciness of the oil produced.